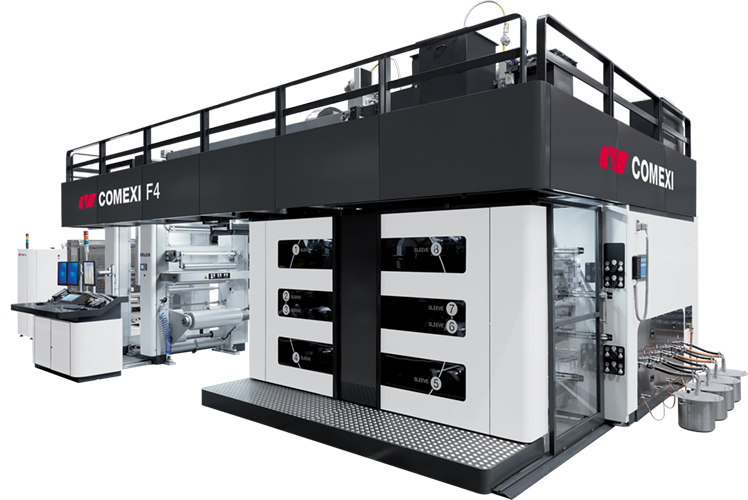

Flexo Printing Products reach maximum quality with its advanced technology precision machinery. Printing machines capable of flexo printing up to 10 colors at a speed of 400 meters per minute ensure the continuity of print quality with its automatic print monitoring system, while providing fast service with non-stop warping and winding systems. Thanks to the Positioning System), the products reach high print quality, while quality continuity is ensured in job repetitions. In this way, the continuity of the work is kept at the maximum level.

The lamination of the films whose flexo printing process is completed is carried out in our modern facilities with solvent and solvent-free lamination techniques. In food products, lamination processes are applied so that the printed surface does not come into contact with food. The products are laminated with two or more ply combinations of BOPP, CPP, PE, PET, BOPA, ALU and paper products. Adhesives complying with food safety standards are used during lamination processes. Moreover, thanks to the lamination process, the shelf life of the packaged products is increased by adding strength and barrier properties to the packages. The lamination processes to be applied vary according to the sectors of the products produced. The decisive factor here is customer expectation.

The last process in production is slitting and bag making. The products, whose printing and lamination are completed, are sliced to the desired size and turned into rolls. If the products are to be used in automatic packaging machines, they are transferred directly to the storage and shipping department. If the products are to be produced as bags, they are cut into bags by cutting machines in accordance with the customer's demand. Pillow type, gusseted, doypack, quattro, zip-lock bag productions are specially offered to customers during the cutting and bag making process. Wicket bags can also be produced for automatic filling lines. With the completion of the last stage in production, the products produced are ready for shipment.